Understanding Cobalt Drill Bits

The Basics of Cobalt Drill Bits

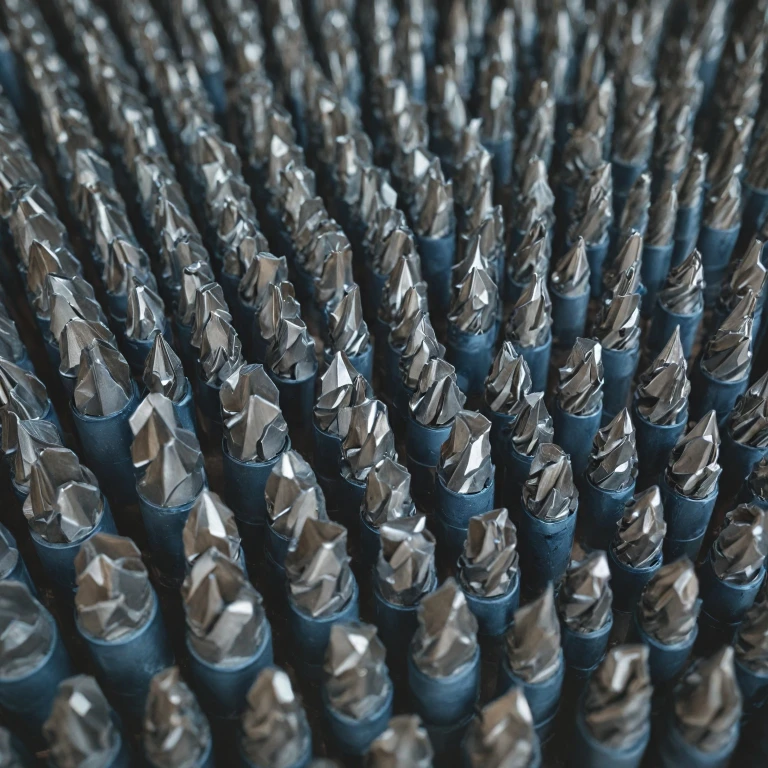

Cobalt drill bits are a specialized form of drill bits designed for demanding drilling tasks, particularly in hard surfaces like stainless steel and cast iron. These bits are composed of a mixture of steel alloy that contains 5-8% cobalt, granting them significant advantages when it comes to drilling in tough materials. The integration of cobalt allows these bits to maintain their hardness even at high temperatures, making them ideal for high-speed applications. ### Why Choose Cobalt? Understanding why cobalt is a critical component of these drill bits involves a recognition of its properties. Cobalt provides the necessary durability and heat resistance, ensuring that the bits can withstand the prolonged friction and heat that results from high-speed drilling. This robustness significantly reduces the risk of the bits softening, which is a common issue with other materials when drilling into hard metals. When you're up to a task that involves cutting through tough metals, having the right tools is crucial. Our article "Enhance Your Cutting Precision with the NGX 24-Inch Clamp Edge Saw Guide" offers insights on similar precision-cutting tools. ### Differentiating Factors Cobalt drill bits are often confused with other types of high-speed steel (HSS) drill bits. However, cobalt bits dare to differ as they offer longer tool life and can perform in more demanding conditions than standard HSS bits. Cobalt bits are distinctive for their intense durability and cutting power, making them indispensable for any toolkit intended for working with metal. ### Use in Cordless Drills For cordless drills, cobalt bits are particularly advantageous as they allow for efficient and precise drilling through various metal materials without much compromise in battery life due to reduced effort required from the motor. When selecting drill bits for metals like stainless steel, choosing the correct type becomes even more pertinent, as we explore further in other sections of the article. In summary, cobalt drill bits are designed to provide optimal performance in tough working conditions, ensuring that your cordless drill is complemented with bits capable of taking on any challenge you present them with.Benefits of Using Cobalt Drill Bits in Cordless Drills

Advantages of Incorporating Cobalt Drill Bits in Cordless Drills

When using cordless drills for various projects, selecting the right drill bits can significantly enhance performance. Cobalt drill bits are favored for their numerous benefits, offering an exceptional drilling experience.- Durability: Made from cobalt steel, these bits are known for their longevity. They can withstand high-temperature applications, making them perfect for drilling into hard metals like stainless steel and cast iron.

- Efficient Penetration: With a split point design, cobalt drills provide rapid penetration. This feature reduces walking and helps you start your hole precisely where you want.

- Versatility: Suitable for various materials, cobalt bits handle metal, wood, and plastic with ease, increasing the functionality of your cordless drill set.

Choosing the Right Cobalt Drill Bit for Your Needs

Factors to Consider for Optimal Performance

Choosing the right cobalt drill bit for your cordless drill involves understanding several key factors that can significantly impact your drilling efficiency and results. Here are some considerations to keep in mind:

- Material Compatibility: Cobalt drill bits are designed for drilling through tough materials such as stainless steel, cast iron, and high-speed steel. If your projects primarily involve these materials, cobalt bits are an excellent choice.

- Size and Length: Cobalt drill bits come in various sizes and lengths, including jobber length and aircraft extension. Selecting the right size and length depends on the specific requirements of your project. For deeper holes, longer bits like jobber drills or aircraft extensions might be necessary.

- Shank Type: The shank of the drill bit should match your drill's chuck size. Most cobalt bits come with a straight shank, but it's crucial to ensure compatibility with your cordless drill to avoid slippage during operation.

- Number of Pieces in a Set: If you frequently work with different materials, investing in a cobalt drill bit set with multiple pieces can provide versatility and convenience. A set often includes various sizes to accommodate diverse drilling needs.

- Special Features: Look for features like split point tips, which help reduce walking and enhance precision, especially when starting a hole. Solid carbide and high-speed steel options may also be available for specific applications.

Understanding Your Drilling Needs

Before purchasing a cobalt drill bit, assess the specific demands of your projects. If you're working with hardened steel, for instance, ensure the bits are capable of handling such materials without excessive wear. The right drill bits for hardened steel can make a significant difference in performance and longevity.

By considering these factors, you can select the most suitable cobalt drill bits that align with your cordless drill's capabilities and your project requirements, ensuring efficient and effective drilling every time.

Maintenance Tips for Cobalt Drill Bits

Preserving the Edge: Proper Care for Your Cobalt Drill Bits

To ensure that your cobalt drill bits maintain their efficiency and longevity, it's crucial to follow a few maintenance practices. These high-speed steel tools are designed to handle tough materials like stainless steel and cast iron, but proper care will keep them performing at their best.

Regular Cleaning and Inspection

- Cleaning: After each use, clean your drill bits with a soft cloth to remove any metal shavings or debris. This prevents build-up that can dull the cutting edge.

- Inspection: Regularly check for signs of wear, such as chips or dullness. A split point bit that is not sharp can lead to inefficient drilling and potential damage to your cordless drill.

Proper Storage Solutions

- Storage Case: Use a designated storage case to keep your bits organized. This prevents them from knocking against each other, which can cause damage.

- Dry Environment: Store your bits in a dry place to avoid rust, especially if you are working with a high number of bits in a set.

Sharpening Techniques

- Sharpening Tools: Invest in a quality sharpening tool to maintain the cutting edge of your cobalt bits. This is especially important for jobber length bits that frequently encounter tough materials.

- Professional Service: Consider professional sharpening services if you're not confident in doing it yourself. This ensures precision and maintains the integrity of the bit.

Cooling and Lubrication

- Lubrication: Use cutting oil or lubricant when drilling through metals like stainless steel to reduce friction and heat, extending the life of the drill bit.

- Cooling: Allow bits to cool naturally between uses to prevent overheating, which can compromise the bit's hardness and performance.

By incorporating these maintenance practices, your cobalt drill bits will remain sharp and effective, ready to tackle any project involving wood, plastic, or metal with ease.

Safety Considerations When Using Cobalt Drill Bits

Prioritizing Safety in Drill Operations

When operating any power tool, safety should always be a priority, especially when using cobalt drill bits in a cordless drill setup. Here are essential safety considerations to keep in mind:- Wear Appropriate Personal Protective Equipment (PPE): Whether you're dealing with cobalt drill bits, high-speed steel, or carbide, ensure you wear protective gear. This includes safety goggles to prevent metal shavings from reaching your eyes and gloves for handling sharp bits.

- Secure Your Workpiece: Before starting your drill, ensure the metal, whether stainless steel, cast iron, or other, is securely clamped. This prevents movement, ensuring precision and reducing the likelihood of accidents.

- Mind the Cordless Drill Speed: The speed at which a drill operates greatly affects its performance and safety. Use the recommended speed settings for the material you're working on, particularly when drilling through hard metals.

- Maintain Proper Drilling Technique: Using a steady hand and applying consistent pressure help prevent the bit from slipping. With split point and jobber length bits cobalt, precision reduces chances of injury and tool wear.

- Avoid Overheating: Extended drilling can cause cobalt drill bits to overheat. Implement cooling techniques, such as using cutting fluid, to extend the life of your bits and prevent accidents.

- Use the Correct Drill Bit for the Job: Different drilling tasks require specific types of bits, whether they're aircraft extension bits, solid carbide, or HSS. Ensure you're using the right bit for the material to maintain safety and achieve optimal results.

Top Brands and Recommendations

Trusted Brands for Quality Bits

When you are investing in cobalt drill bits to enhance your cordless drill set's capabilities, choosing a reputable brand ensures reliability and performance. Here are some of the top brands known for their high-quality drill bits:- DEWALT: A well-known name in the industry, DEWALT offers durable cobalt drill bit sets that provide precision and long-lasting performance. Their bits are crafted to handle a wide range of materials, including stainless steel and cast iron.

- Bosch: Known for their engineering excellence, Bosch drill bits are designed with a split point to prevent walking and ensure a clean start. These are especially useful for working on hard metals.

- Milwaukee: Offering robust cobalt drill bits with jobber length, Milwaukee is praised for its high-speed steel bits that balance toughness and sharpness.

- Irwin Tools: Widely recognized for creating versatile and reliable bits, Irwin provides a comprehensive range of cobalt alloy bits suitable for both professional and DIY applications.

- Makita: With a focus on precision and durability, Makita's bits are designed to withstand high-speed applications, making them a solid choice for intense drilling tasks.

Recommended Sets for Your Toolbox

For those looking to purchase a comprehensive set, numerous options are available, targeting various needs:- DEWALT Cobalt Drill Bit Set: Available in high-quality pieces cobalt assortments, these sets are perfect for tackling hard steel cast materials.

- Bosch CO14B 14 Pc. Drill Bit Set: This set includes bits with a carbide drill coating for enhanced durability and precision, ideal for stainless and hardened steel.

- Irwin Industrial Tools 3018002 Cobalt M-35 Metal Index Drill Bit Set: Featuring a range from 1/16-inch to 3/8-inch, this set is designed for longevity in tough materials.

- Milwaukee Thunderbolt Black Oxide Jobber Drill Bit Set: Providing high-speed, versatile performance, these bits are manufactured for various metalworking tasks.